- Home

- Composite Decking

- MANHATTAN composite decking

MANHATTAN composite decking

Striking wood appearance, whether smooth or grooved !

- Exclusively at Sylvalliance points of sale

- 360° co-extruded decking

- Grooved surface - Matte brushed smooth surface

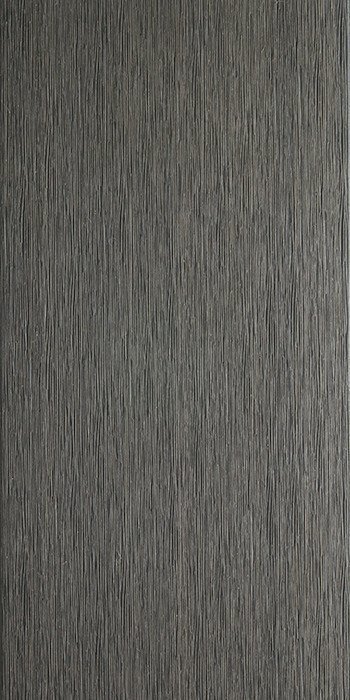

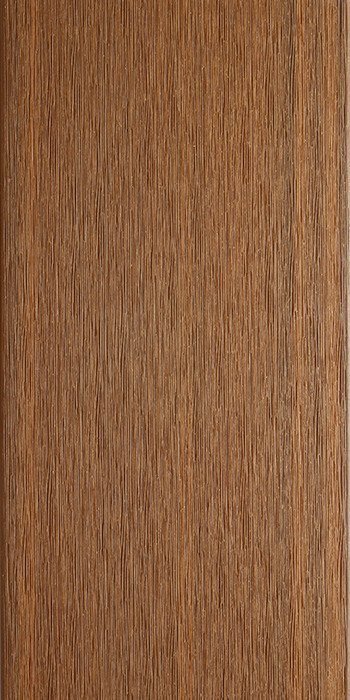

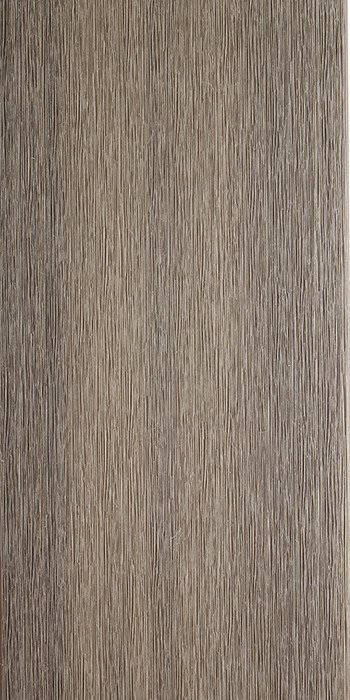

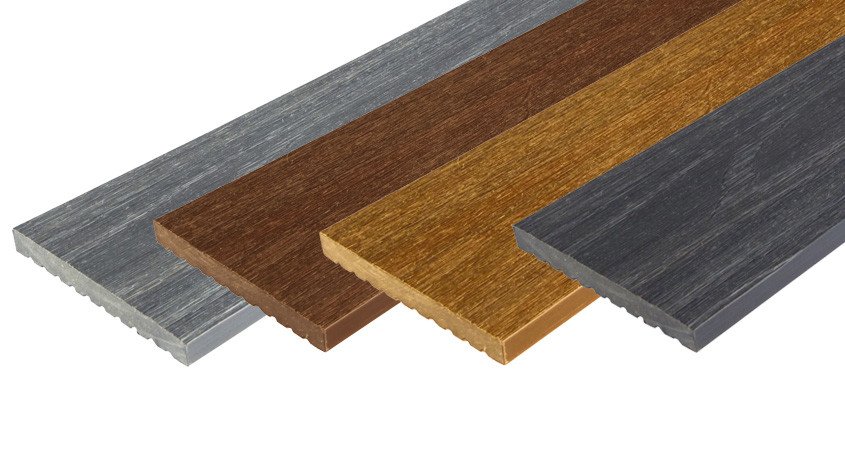

- 4 multi-chromatic colours

- Stain and fading resistant

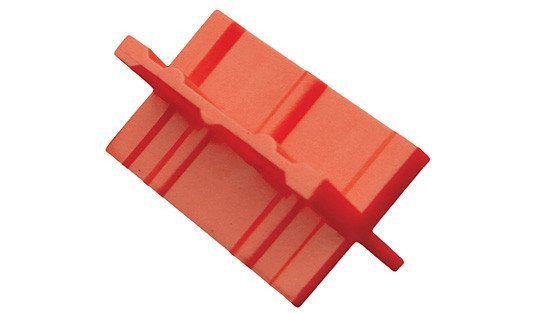

- Removable board with Cobra® Hybrid 8-18 clips

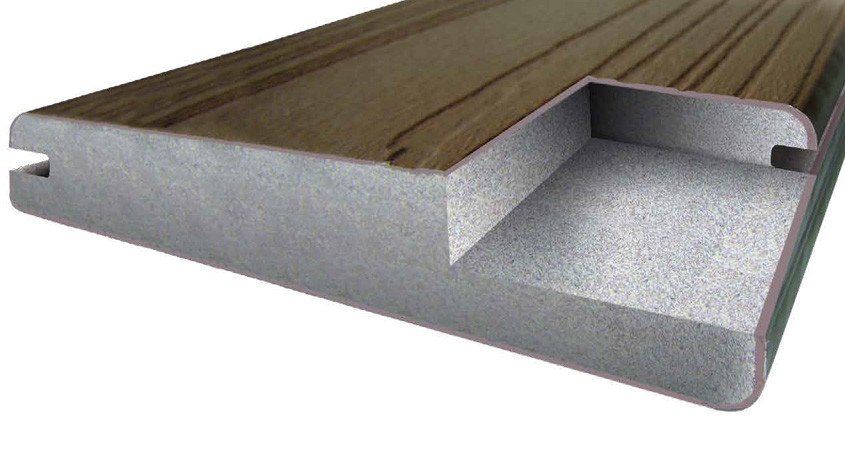

- 360° co-extruded protection

- Reversible profile: 2 effective sides

- Stainless steel fastener groove

48-72h delivery

Characteristics

screw-in board: 22.5 x 138 x 2400mm

Finishing skirting board: 10 x 84 x 2400mm

Intense, striking colours

A fine layer of polyethylene covering the entire board efficiently protects the composite wood against water and any moisture being picking-up. Expansions recorded are very low, with only 1 mm per linear meter when exposed to a 30° variation temperature.

Co-extruded layer

A fine layer of polyethylene covering the entire board efficiently protects the composite wood against water and any moisture being picking-up. Expansions recorded are very low, with only 1.07 mm per linear meter when exposed to a 30° variation temperature.

The board is completely rain-proof, with rain flowing off without letting water penetrate the protected composite wood. UV-resistant additives are also added to this fine protective layer to avoid any fading over time.

This over-layer is applied at the same time as the extrusion to obtain a fusion of materials and perfect adherence over time.

No fading and no stains

In addition to their resistance to UV for 20 years, co-extruded MANHATTAN boards require very little maintenance. All common stains such as grease, wine or ketchup can be cleaned easily using soapy water.

However, washing your decking at least once a year to remove moss and lichen with a high-pressure washer (120 bar maximum) is recommended tougher stains may be washed with mild solvents without risk of fading.

Fastening with Cobra® Hybrid clips

MANHATTAN boards must be installed in accordance with the installation instructions using Cobra Hybrid 8-18 stainless steel clips. A bag of 90 clips fastens about 5 m2of boards.

These new dual-material clips efficiently maintain boards on joists using underside grip sets. Stainless steel screws are already pre-assembled on clips, thus providing considerable time savings during installation. Moreover, the stainless steel screws are self-drilling in softwoods, exotic woods and aluminium joists

MANHATTAN boards can be easily removed without having to disassemble the entire deck. Joist spacing (centre-to-centre distance) must be at most 40 cm for MANHATTAN boards.

Fiberdeck guarantees that, for a 20-year period under normal and correct service conditions, and under installation conditions in compliance with instructions written by Fiberdeck, MANHATTAN boards will not be subject to any defect related to their manufacturing, cracks, splinters, delamination, rotting or structural damage caused by fungi, wood-eating insect or termite attacks.

Fiberdeck guarantees the resistance of MANHATTAN deck boards to stains and fading, subject to compliance with instructions for installation and use in residential applications.

Cobra Hybrid 8-18 clip installation

95% recycled raw materials

MANHATTAN composite deck boards are environmentally-friendly products. 95% manufactured with raw materials from the recycling industry, these boards are also entirely recyclable.

High-density polyethylene (HDPE) comes from the recycling of plastic waste (plastic bottles), and the wood fibres come from sawdust from manufacturers such as furniture makers.

The manufacture of MANHATTAN composite deck boards does not harm tropical forests; it is an attractive alternative to exotic woods.

Screw-in finishing boards

A range of screw-in boards, identical to MANHATTAN boards, 22.5 x 138 mm section, but without grooves on the sides, may be used to create sundecks for swimming pools, stairs, floor openings and also a finishing strip around the deck.

Stainless steel Cobra WPC screws, 5 x 63 mm, which resist rust and are available in the same colour as the boards for more discretion, are used to fasten skirting and finishing boards.

Finally, using an aluminium angle bar to ensure the peripheral contour of the deck and mask the junction between two grooved boards is always possible.

Skirting boards

A range of 10 x 84 mm skirting boards, grooved on one side and smooth on the other, available in four colours, complete the MANHATTAN board range, making it possible to create deck contours at a height of about 10 cm.