- Home

- Composite Cladding

- WEO® 60 composite cladding

WEO® 60 composite cladding

A modern open-joint profile cladding

- Stunning exotic wood imitation

- Modern open-joint appearance

- 20 years colour guarantee

- Easy to install

Livraison 48-72h

Characteristics

ΔE=2,59

dL≤ 50,0.10-6 Passe

EN 13501-1 + A1

D - s1, d0

- Co-extrusion layer

- Tongue and groove assembly

- Maintenance free

Water-Resistant Facade Cladding With A Real Wood Look

Bardage bois : chaleureux mais trop cher à entretenir ? La solution est le bardage composite WEO !

Les panneaux de bardage WEO sont étanches . La couche de coextrusion protège le matériau composite en bois, créant une barrière étanche contre la pénétration de l'humidité . Lorsqu'il est installé horizontalement, le profil trapézoïdal permet l'évacuation de l'eau de pluie et évite la stagnation de l'eau. Notre technologie exclusive de coextrusion est garantie 20 ans contre la pénétration d'humidité, les attaques d'insectes et surtout contre toute décoloration ou décoloration .

Le bardage composite WEO allie la durabilité de la coextrusion et l’ aspect chaleureux du bois. Le profil en faux joints ouverts, tendance et moderne, rythme la façade tout en préservant le caractère naturel et la chaleur du bois. Les nuances aléatoires des couleurs renforcent l'impression réaliste d'un matériau naturel et non traité.

La solution composite vous permet d’obtenir l’aspect chaleureux d’un bardage en bois naturel sans entretien ni souci coûteux.

Quick and Easy to Install

Le profil WEO 60 est stabilisé par sa face inférieure, ou couche de support. Ses grandes alvéoles sont également renforcées au milieu pour une meilleure résistance aux chocs .

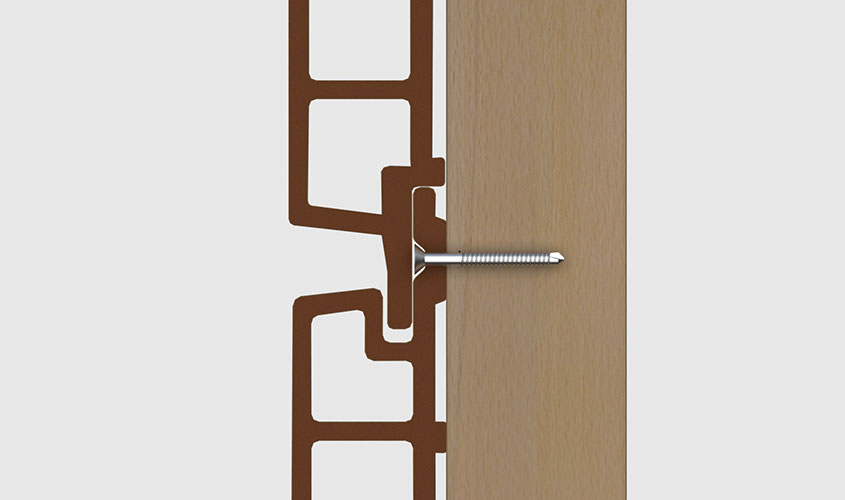

Le bardage composite WEO 60 se pose de la même manière que le bardage WEO 35, à l'aide de vis colorées ou d'une vis inox vissée dans la rainure et languette encastrées. Le profilé comporte également des pattes au dos pour assurer la ventilation entre le support et l'habillage.

Le revêtement des panneaux WEO est imputrescible et ne présente aucun risque de reprise d’humidité. La circulation de l'air sert uniquement à aérer le support.

A 20 Year Warranty Against Discolouration and Fading!

Tous les bois, et même certains bois composites de première génération, ont tendance à se décolorer ou à se décolorer avec le temps. Même le bois traité en usine avec un saturateur ne peut être garanti en toute sécurité que jusqu'à 5 ans.

Le bel aspect gris argenté du bois est apprécié pour sa couleur, mais selon son exposition et son âge, il finira par se dégrader et présenter des décolorations non homogènes qui altèrent son esthétique.

WEO composite cladding allows you to get that exclusive wood look without worrying about fading or discolouration. WEO composite cladding is covered with a thin layer of anti-UV treated co-extrusion, which protects the cladding boards from water and sun damage. This polyethylene-based waterproof film considerably reduces facade maintenance and maintains board colour over time. The film is fused to the core of the composite profile and will not detach.

We guarantee that your WEO composite cladding will retain its original color for many years to come.

A Modern and Trendy Profile

Wooden siding is becoming increasingly popular. Boards with distinct designs and small joints break the uniform and give rhythm to a facade. The installation of this type of plank is often long and tedious and requires very stable wood.

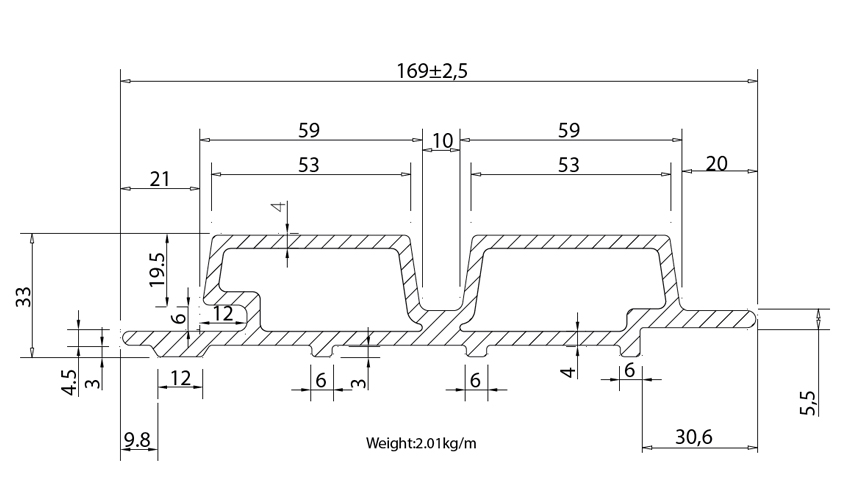

WEO 60 cladding has a false skeleton profile that allows it to be installed quickly and easily. Two possible installation choices, vertical or horizontal, accentuate the perception of height or depth for exterior facades. The 60mm wide slats are evenly spaced 10 mm apart. They are lightweight, stable and easy to install with our mounting system.

It is also possible to mix the WEO 35 and WEO 60 profiles to create more variation. These composite panels perfectly imitate the open-joint appearance of wood cladding and create a striking, modern facade.

Ideal for Outdoor insulation

The insulation of our buildings is an important issue in helping to reduce our carbon impact.

The honeycomb profile of WEO facade cladding, in combination with insulation, provides an insulation solution that is very close to that of wood. WEO cladding is more durable than wood cladding and requires less maintenance. It is also an ideal product for places that are exposed to bad weather conditions (humidity, sun, moisture, etc.).

WEO composite boards are fully compatible with External Thermal Insulation Composite Systems (ETICS), and can adapt to any insulation system (e.g. RedAir System). WEO composite cladding is the perfect choice for renovations, extensions, single-family homes, residential buildings or public-access buildings.

A Remarkably Natural Looking Imitation Wood

The texture of WEO cladding is similar to that of a living material. It is made up of a set of micro-reliefs and depressions, that resemble natural wood. To the naked eye, the product looks as if it has natural surface fibers.

In order to further enhance that real wood look, the colors on the cladding are not homogeneous. They are composed of several multi-colored pigments that randomly mix to mimic the grain of a wooden plank.

When compared with natural wood, the resemblance is striking. But that's where the comparison ends, because, unlike wood, WEO cladding is extremely durable and is insensitive to light and UV discolouration. The material is composed of sawdust that is mixed with polyethylene. This polyethylene-based waterproof film considerably reduces façade maintenance and maintains board colour over time. The original colour of WEO cladding is guaranteed for up to 20 years. WEO cladding is also completely resistant to weather and insect infestation. With WEO cladding you get a natural, warm wood look that is guaranteed to last.

A stable cell profile with lugs

The WEO®60 profile is stabilized thanks to its underside.

The WEO®60 composite cladding structure is equipped with lugs on the backs of boards, which naturally create a thin space for air between the support and the siding. In vertical installations, they help install boards on a simple wood or metal frame only. Another advantage, the WEO® board coating is rot-proof and has no risk of any moisture pick-up. Air circulation is only for ventilation of the support.

A range of accessories to make finishing perfect

The WEO® range of finishing accessories includes an F-profile and a clip-on corner kit for finishing external corners. Both products are 3m long, made from aluminium and painted in the same colour as the boards to give a stylish finish.

The clip-on corner kit, with a limited overlap of 50mm, provides a refined and discreet finish. The F profile allows WEO® boards to be inserted without prior cutting.

Other cladding profiles are detailed in the Technical Guide. These should be custom-made by specialised sheet metal fabricators according to the project's specific requirements, using aluminium sheets with a thickness of 10/10, 15/10 or 20/10 or galvanised steel sheets with a minimum thickness of 7.5/10 (see technical specifications in the Technical Assessment).

WEO® 60 cladding is composed of a mixture of sawdust (50%) and high density polyethylene (40%). This composite material used in the manufacture of WEO cladding comes from 95% recycled products and is 100% recyclable. Polymer (PEHD) is the result of reprocessing recycled plastic waste, more specifically, waste from plastic bottles. The wood particles are recovered from reusable waste created by the wood industry.

WEO-Facade Cladding contains no toxic products and there is no risk of VOC emissions. It is completely safe to have in your home, business or any public space. WEO products are a great ecological alternative to tropical wood.