North American influence

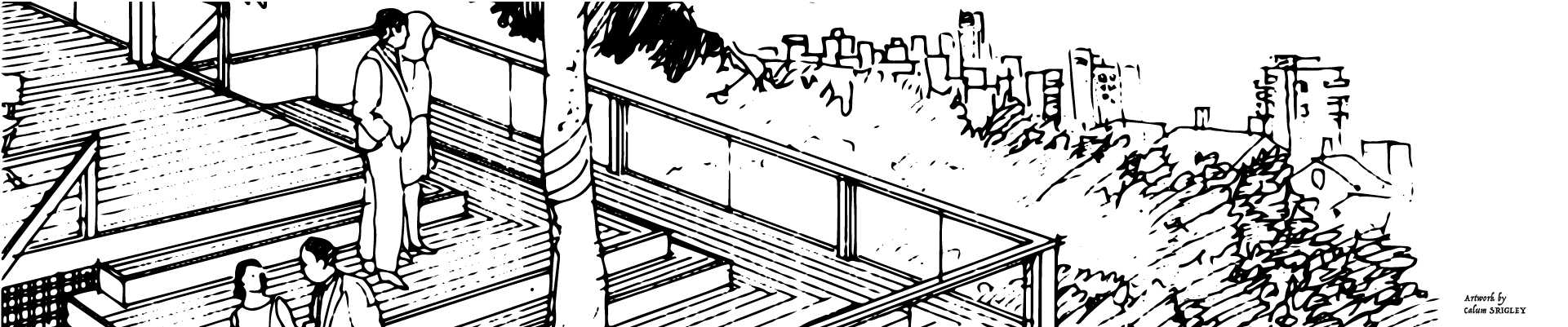

A study trip to Canada and the USA in 1993 started it all. Nicolas TANT, then a young graduate engineer from the École Supérieure du Bois de Paris, discovered a new way of life around "decking" which would reverberate some 15 years later. At the beginning of the 2000s, the garden in Europe becomes a new living room, but also a space for relaxing and socialising. Wooden decks experience an unprecedented boom. With all this excitement at the end of the 90s, composite wood makes its appearance in the USA to offer an attractive alternative to wood. It offers better durability and, above all, simplicity of maintenance. Wood is a warm, unique and authentic material, but it requires regular maintenance. Except for exotic woods, its lifespan is limited. They are a mixture of plastic and wood that revolutionize the decking market. Formulations are constantly improving to ensure better durability.